TSV CUTTING is a company from Šabac specializing in laser metal processing and manufacturing a wide range of steel and aluminum products. Our team with more than 15 years of experience in this field successfully combines knowledge, precision and modern technology in order to offer our clients top quality service.

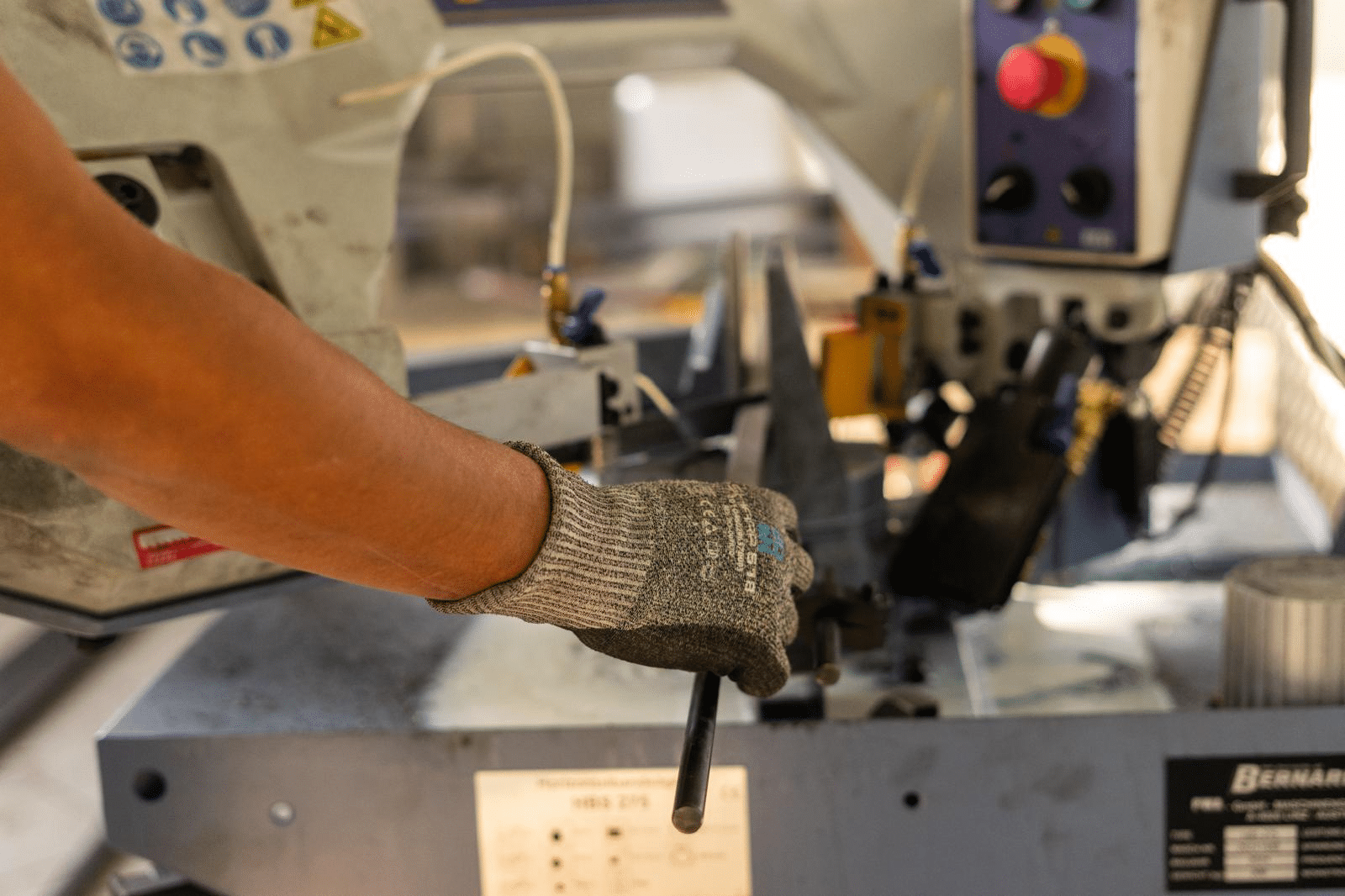

Laser cutting of sheets is the most precise and fastest method of metal processing. Using modern fiber laser technology, we ensure clean and accurate cuts without additional processing. We cut sheets of various thicknesses and materials, including steel, aluminum and prochrome. Our clients receive elements ready for further assembly or finishing, without material loss and deformation. Thanks to modern equipment, we can realize even the most complex shapes and geometries. In addition to serial production, we also make smaller batches and individual pieces. We pay special attention to the speed of delivery and the quality of each product. Our goal is to ensure maximum efficiency and reliability in all types of projects.

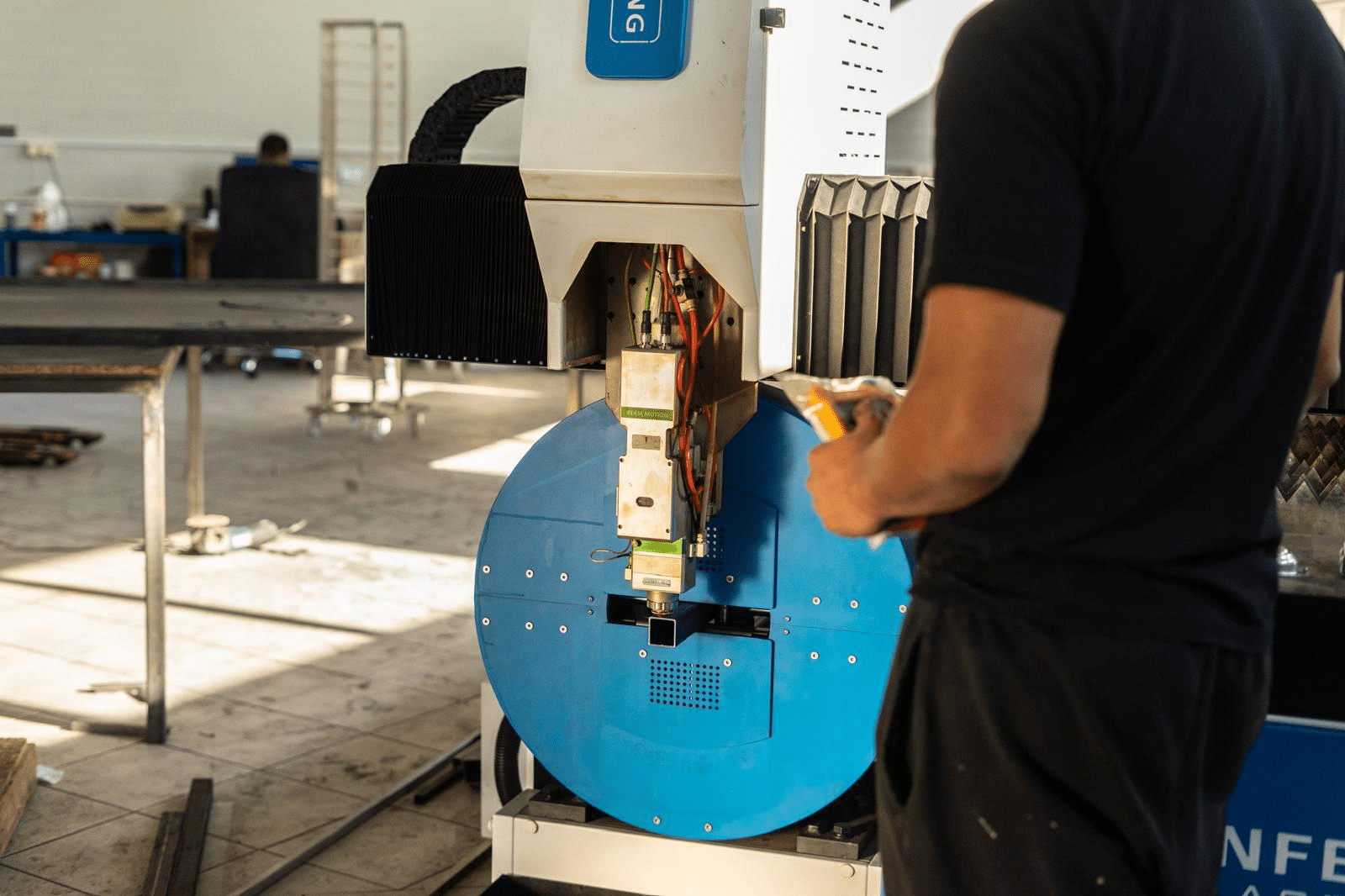

Laser pipe cutting enables the creation of precise and complex cuts on round, square and rectangular pipes. This technology is used for the preparation of structural elements, decorative pipes, as well as special parts for industry. We offer our clients the possibility of creating unique shapes and details that cannot be obtained by classical methods. Our cuts are accurate, with no edges that require additional processing. We do both individual and serial orders, depending on the needs. Laser cutting of pipes saves time and money because it eliminates additional processing processes. All elements are ready for welding, assembly or installation. In this way, we guarantee long-lasting and aesthetically quality solutions.

Bending of sheets on CNC presses enables the production of precise angles and shapes without damaging the material. Our equipment and expertise guarantee that each form is executed in accordance with the client’s technical documentation. We bend sheets of various thicknesses and dimensions, from the simplest to the most complex. This process is crucial for the manufacture of casings, panels, supports, profiles and other structural elements. In addition to the standard ones, we can also make non-standard shapes according to your requirements. Our experts take care of every detail so that the final product is accurate and functional. This enables quick assembly and simple installation. Our approach ensures quality solutions and maximum accuracy.

Metal plastification is a process that protects and beautifies metal surfaces. This procedure extends the life of the metal, protecting it from corrosion, scratches and external influences. We use quality powder paints that are applied in an electrostatic field and then fixed in a furnace at a high temperature. We offer our clients a wide selection of colors and finishes – from matte and glossy to special textures. Lamination is suitable for industrial parts, but also for decorative items. This process gives the metal a beautiful and long-lasting appearance without the need for additional maintenance. All surfaces are carefully prepared before plasticizing to ensure perfect adhesion of the paint. In this way, clients receive products that combine aesthetics and resistance.

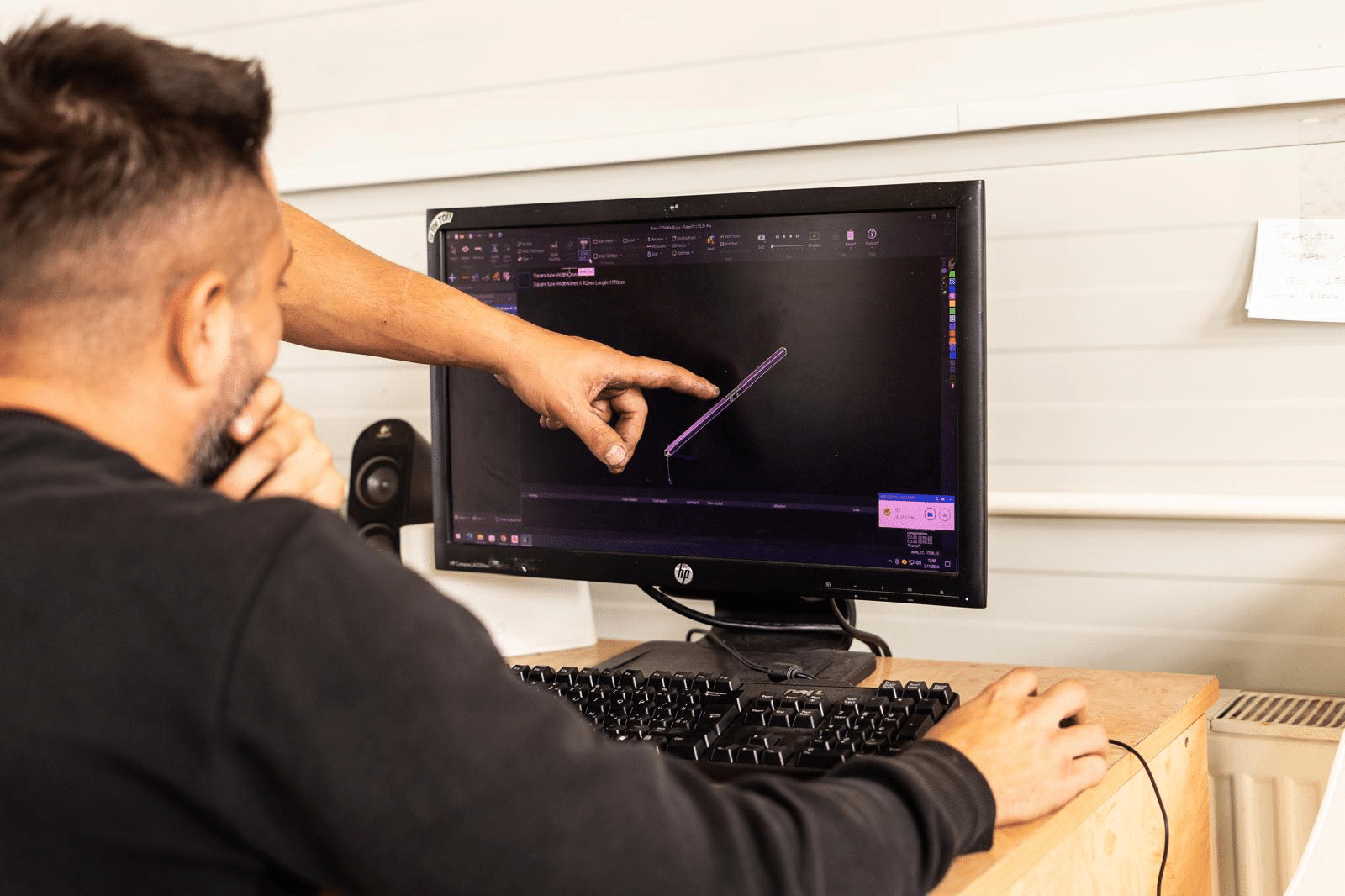

3D modeling and design are the basis of every quality product. Our team uses modern software to create detailed models and simulations. In this way, clients can see in advance what their product will look like. This phase allows avoiding production errors and significant savings in time and materials. Depending on the needs, we make models for industrial components, constructions, but also decorative elements. In addition to the visual representation, we also provide all the technical parameters needed for further production. Our team collaborates with clients throughout the process so that the final solution is fully tailored to their wishes. We combine creativity and engineering precision in every project.

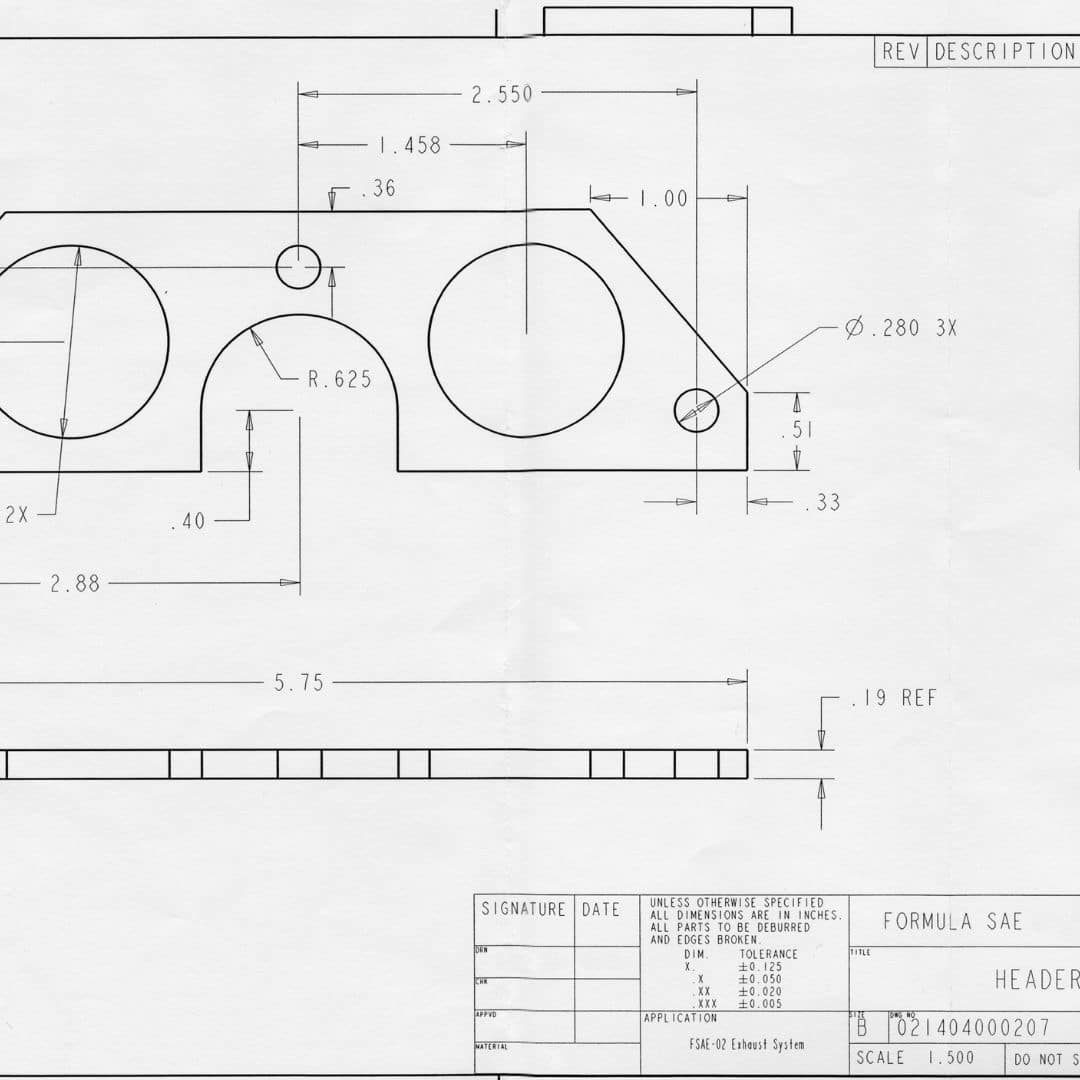

Production of technical documentation is a key part of any serious production. TSV CUTTING offers professionally prepared documentation for all types of metal structures and products. The documentation contains detailed drawings, dimensions, materials and technological procedures. In this way, we ensure that all participants in the process have clear guidelines. Our team uses modern software tools to make the documentation accurate and transparent. We facilitate the production, assembly and quality control process for our clients. We also prepare documentation for existing structures, when reconstruction or upgrading is necessary. Our documentation is in accordance with valid standards and norms. This ensures that the final products are functional, safe and long-lasting.

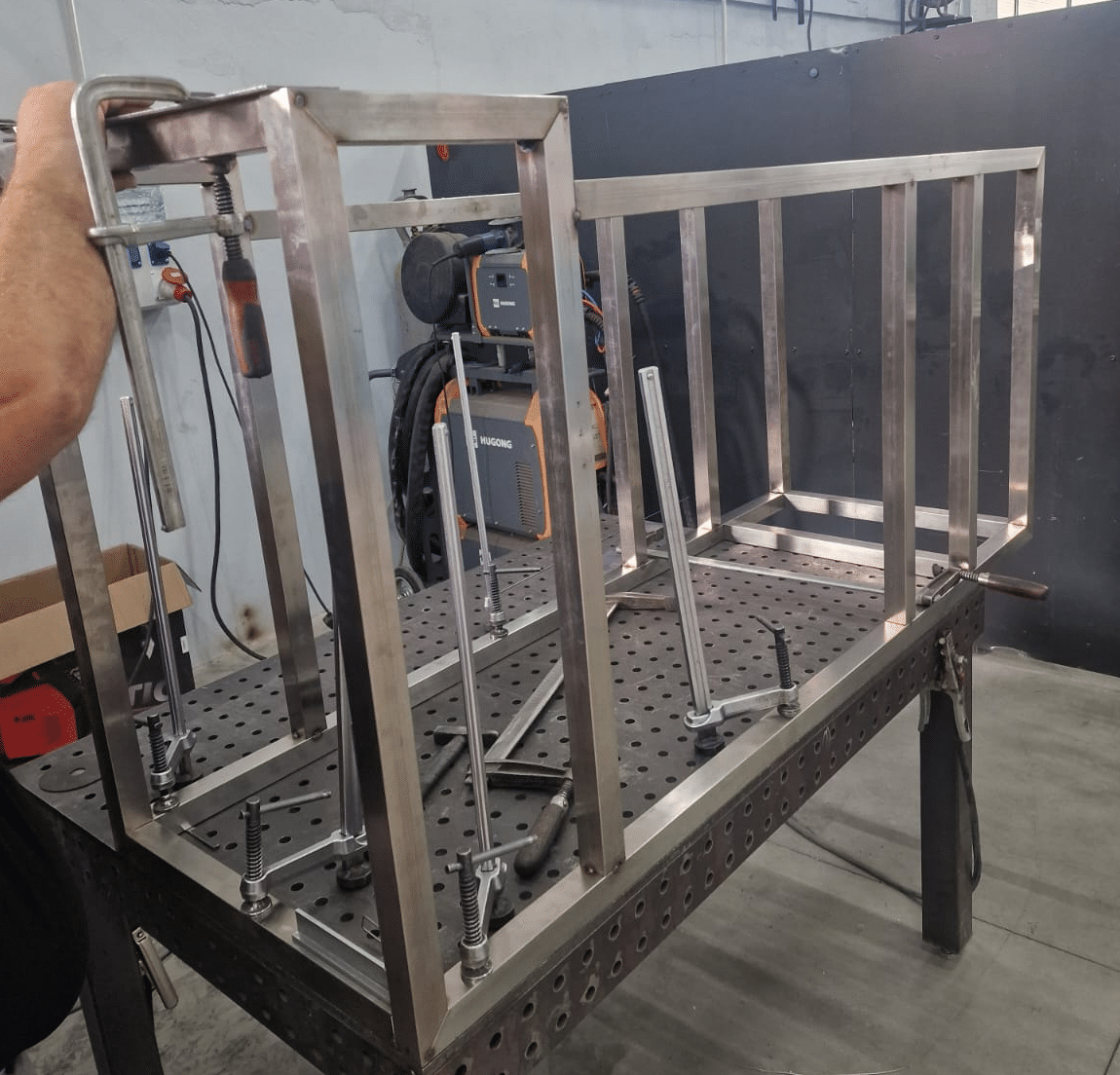

Manufacturing and remodeling of steel structures includes a wide range of services – from simple supports to complex structures. We make structures for industry, construction, interiors and exteriors. Our team has experience in creating new solutions, but also in modifying existing ones. Modifications include adjusting dimensions, strengthening structures and aesthetic finishing. We use quality materials and modern processing technologies in our work. We pay special attention to load capacity, stability and durability. We offer our clients a complete process – from design to final assembly. Our approach ensures that every construction is functional, safe and visually appealing.

We specialize in the manufacture of stainless steel structures for rafts and floating units. These projects require special attention due to constant contact with water and wet environments. Stainless steel is the ideal material because it offers corrosion resistance and durability. Our team makes all kinds of structures – from basic supporting frames to decorative elements. We also make staircases, railings, platforms and special accessories according to client requirements. Constructions are designed to withstand various weather and mechanical influences. In addition to construction, we also provide remodeling and maintenance services for existing structures. Our works combine functionality, aesthetics and reliability.

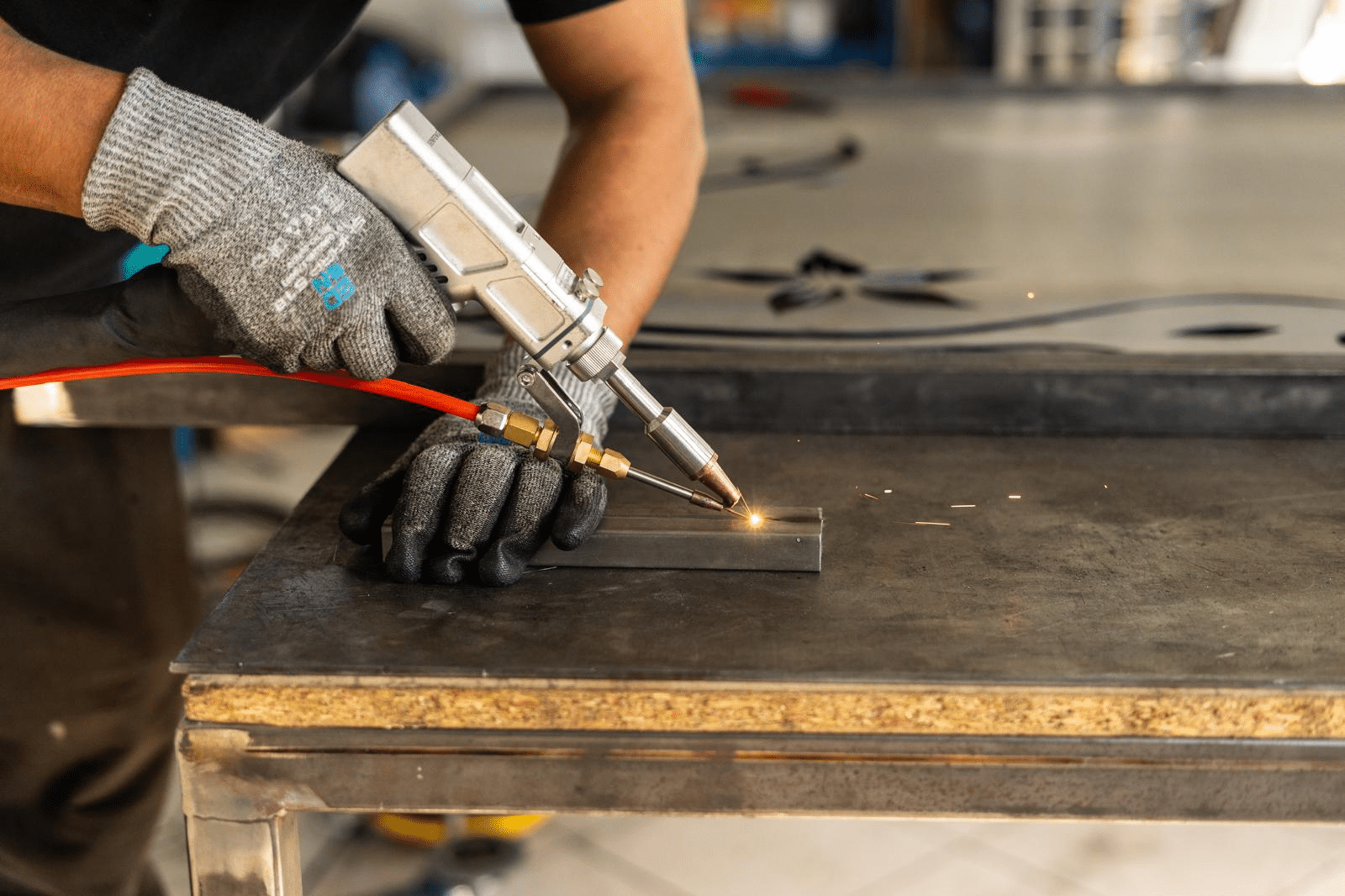

Laser welding is a modern technology that enables quick and precise joining of metal parts. Compared to classical welding, this method produces cleaner joints with minimal deformations. It is suitable for thin materials, but also for parts where maximum accuracy is required. Our clients get aesthetically perfect joints without the need for additional processing. We use laser welding for various industrial components, decorative elements and parts that require high precision. The process is fast and economical, which shortens the delivery time. Our team has knowledge and experience in working with different types of metals. This ensures reliable results and long-lasting solutions.